Video

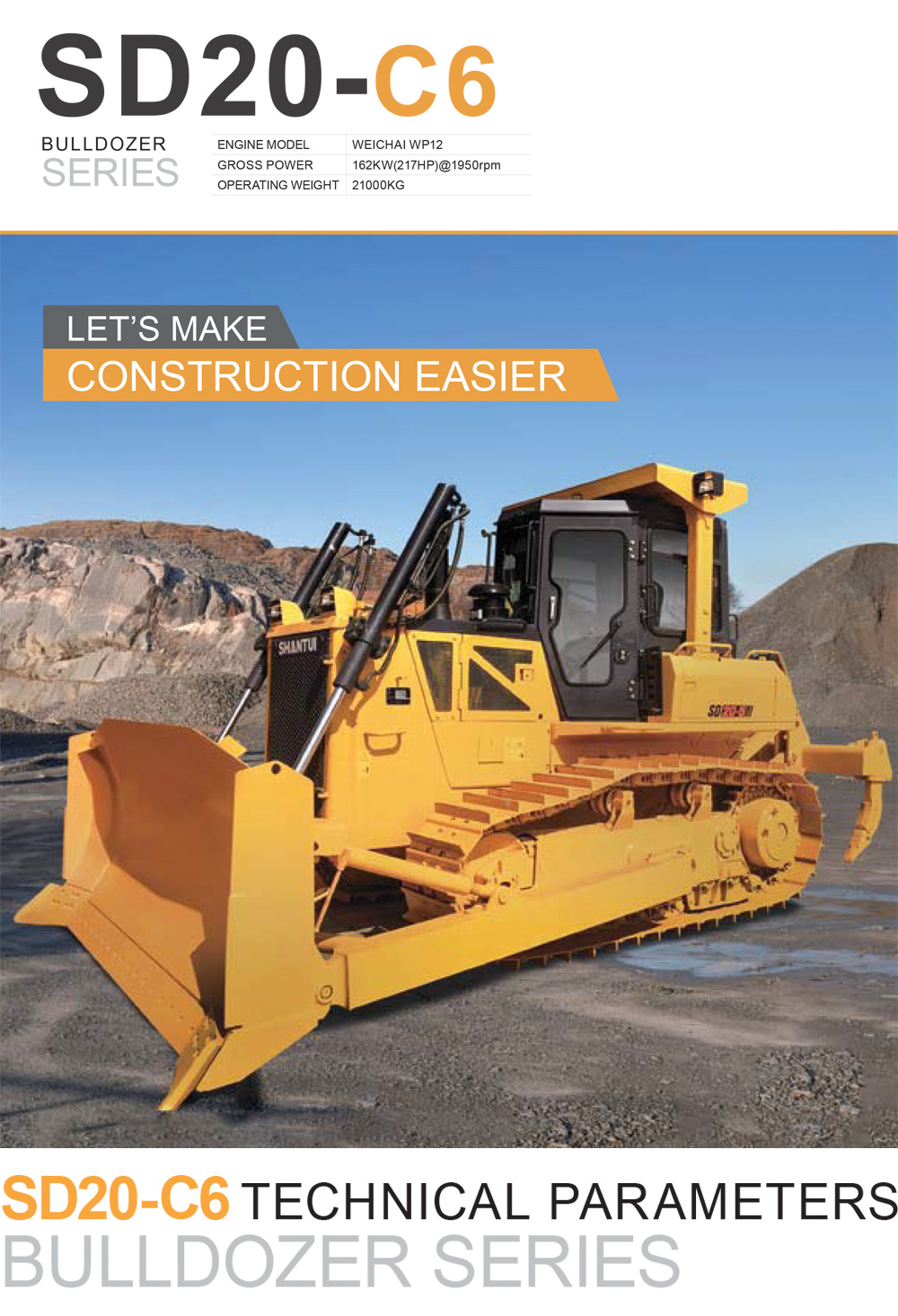

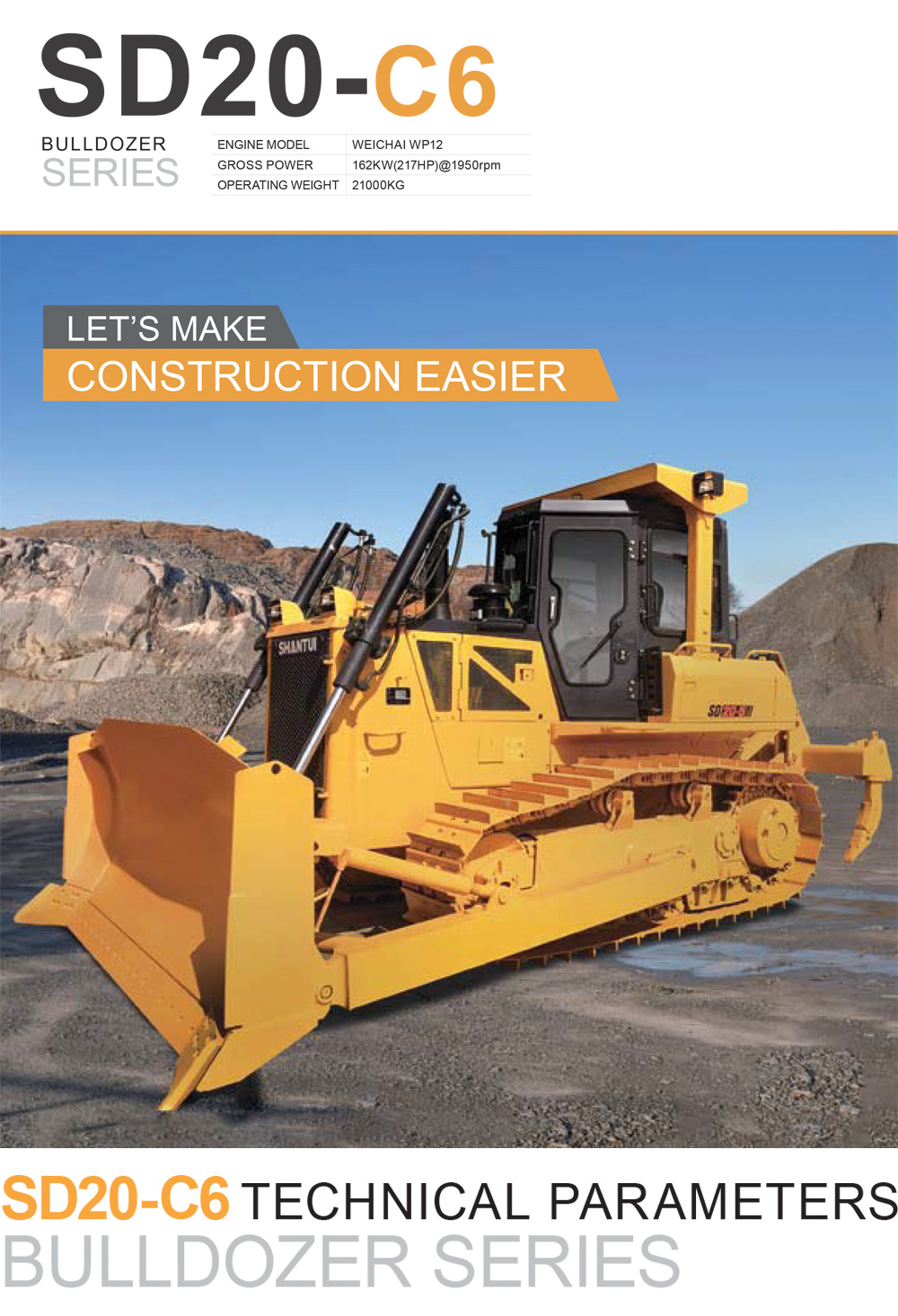

Product Display

Certificate

Working Adaptability

Parameter

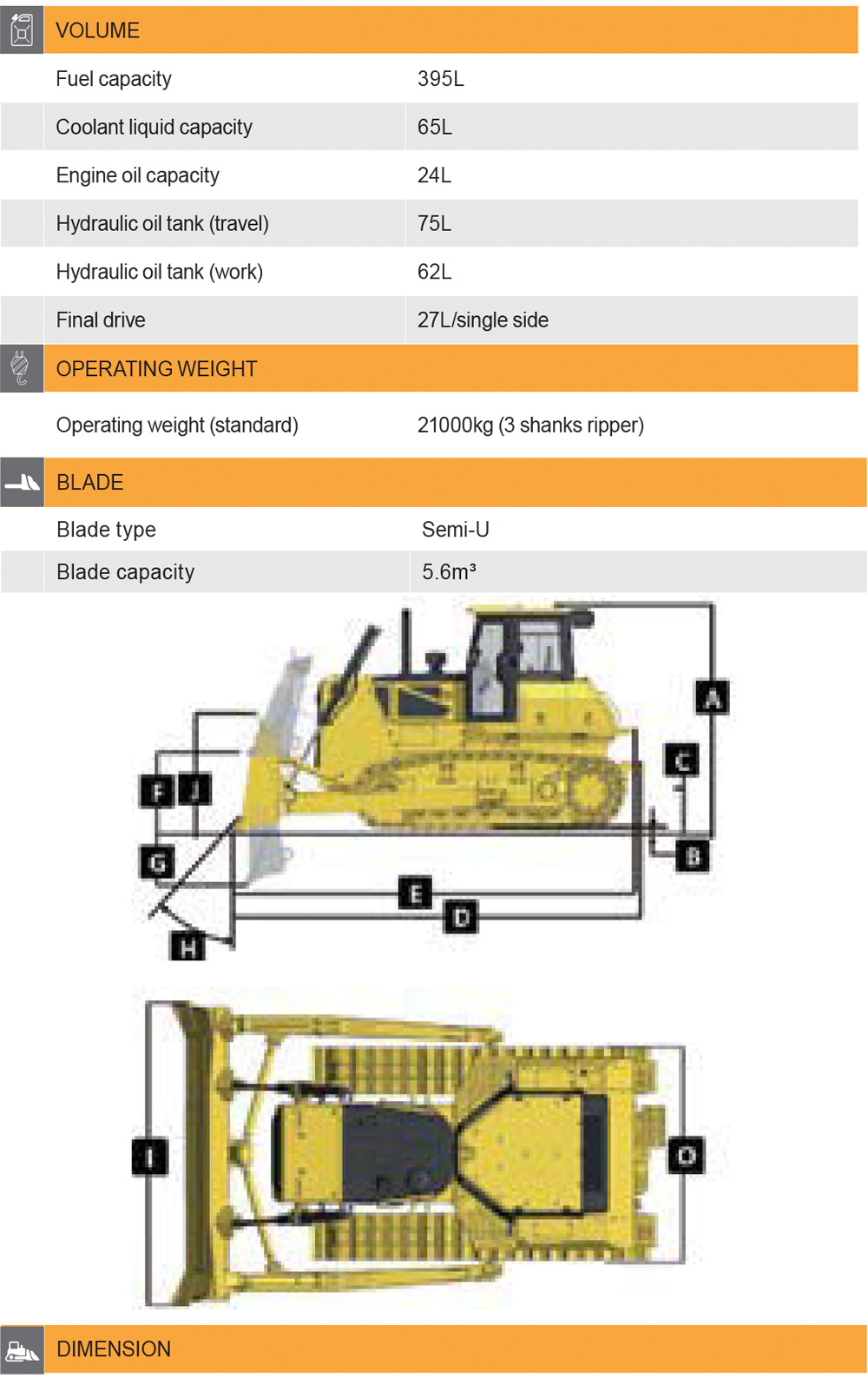

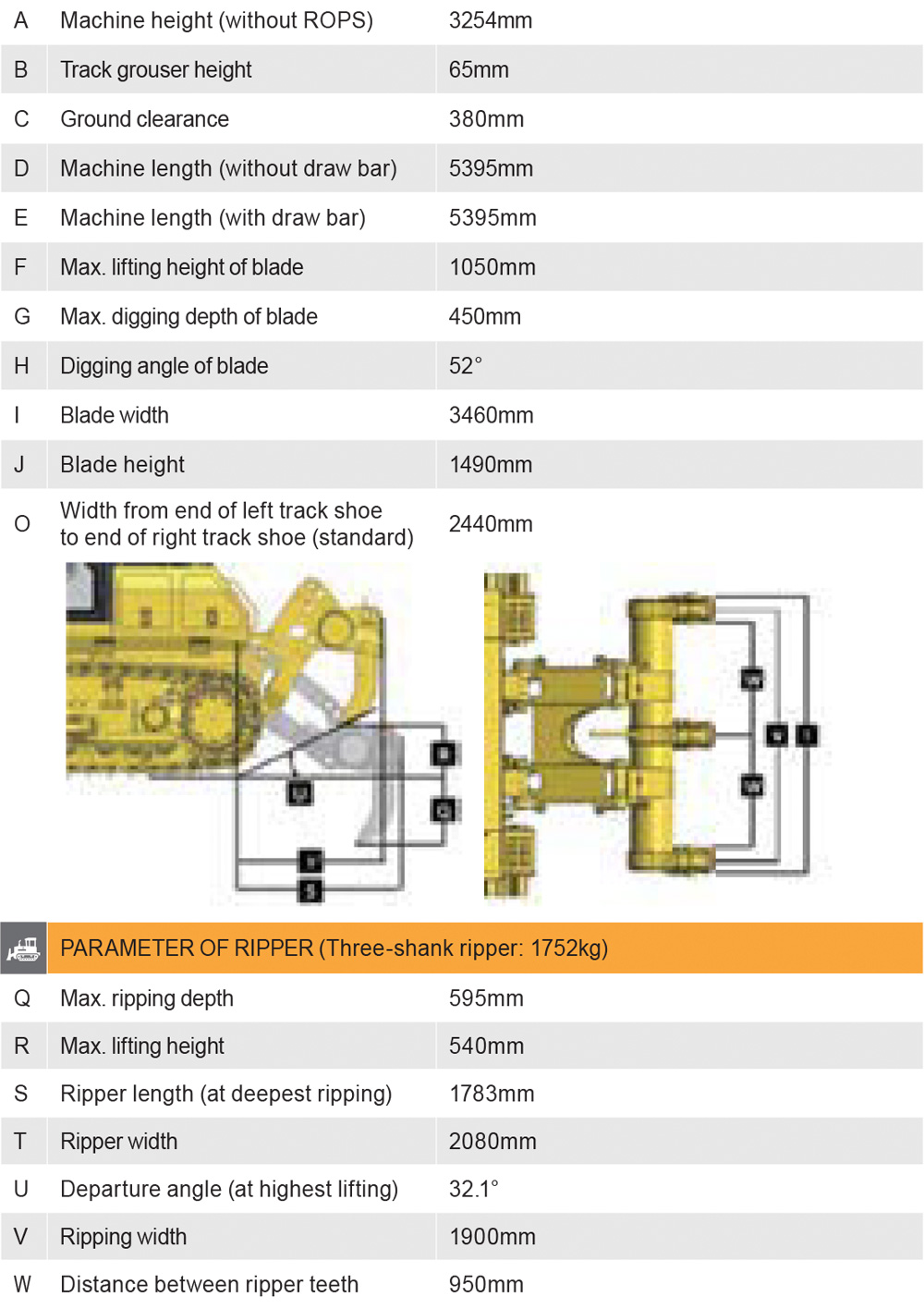

| Parameter name | Standard version |

| Performance parameters | |

| Operating weight (Kg) | 21000 (Including ripper) |

| Ground pressure (kPa) | 60.5 |

| Engine | |

| Engine model | WP12 |

| Rated power/rated speed (kW/rpm) | 162/1950 |

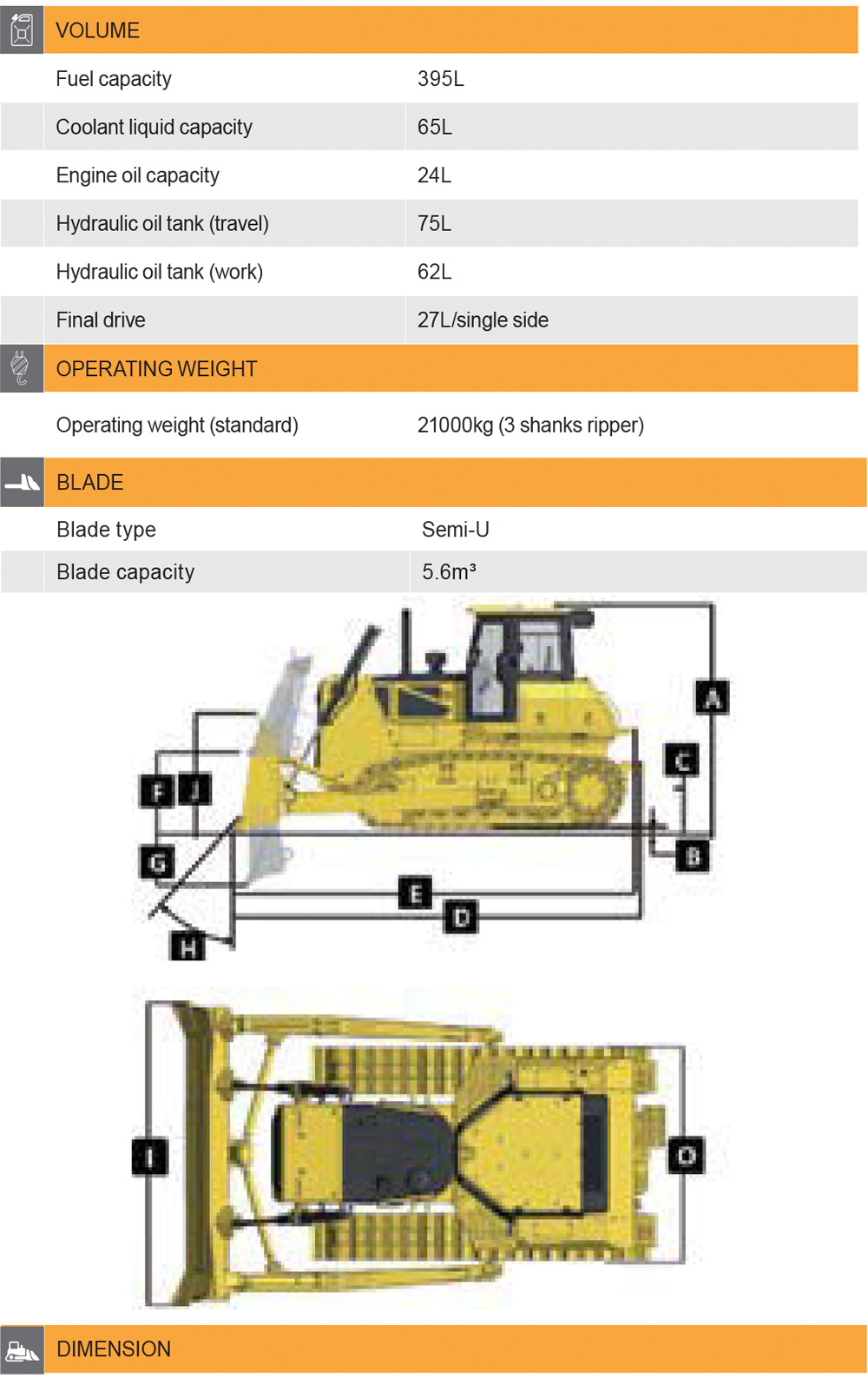

| Overall dimensions | |

| Overall dimensions of machine (mm) | 6805*3460*3305 |

| Driving performance | |

| Forward speed (km/h) | 0~3.9/6.8/10.6 |

| Reversing speed (km/h) | 0~5/8.6/13.4 |

| Chassis System | |

| Center distance of track (mm) | 1880 |

| Width of track shoes (mm) | 560 |

| Ground length(mm) | 2675 |

| Tank capacity | |

| Fuel tank (L) | 415 |

| Working device | |

| Blade type | Semi-U blade |

| Digging depth (mm) | 450 |

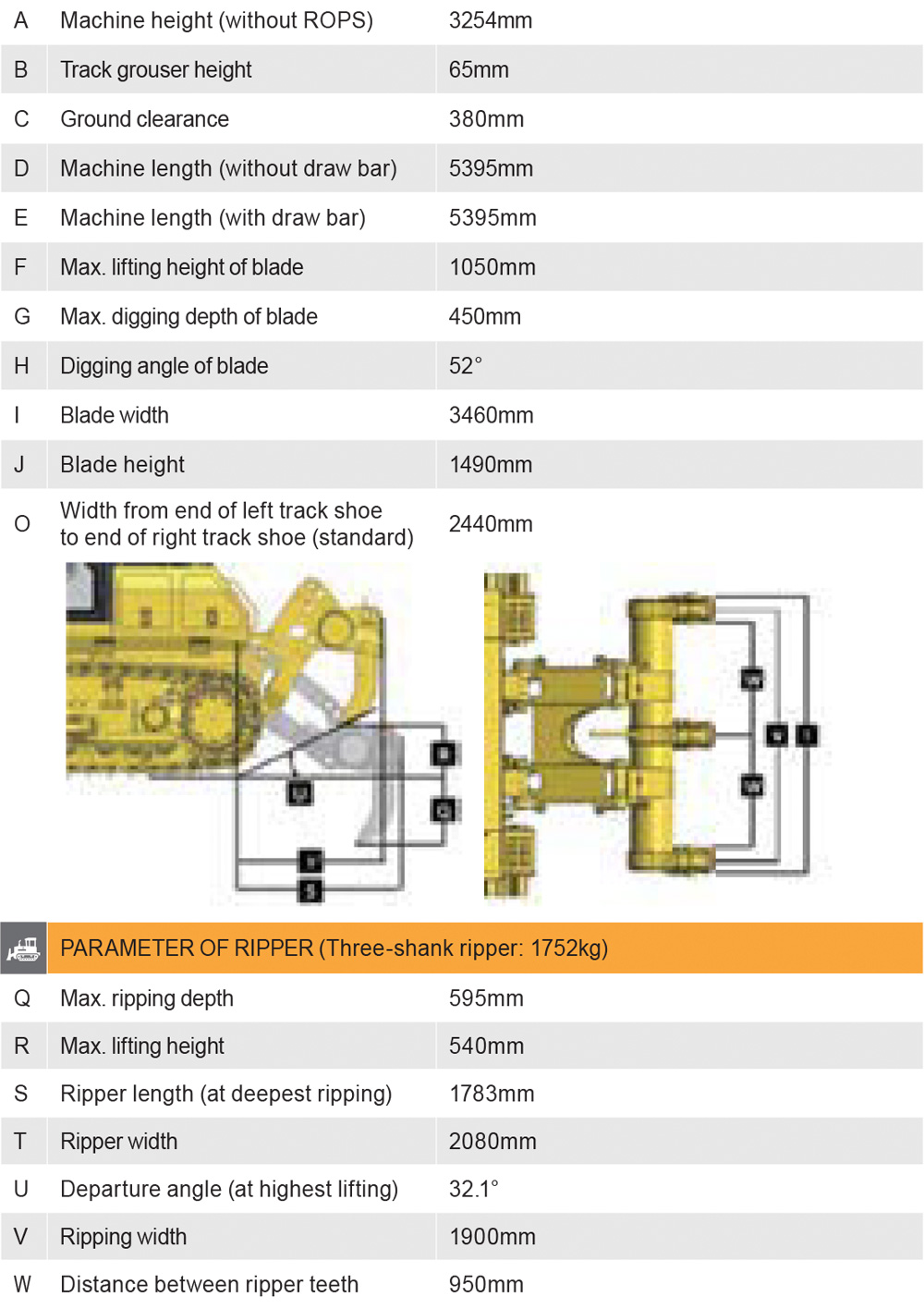

| Ripper type | Three-tooth ripper |

| Ripping depth (mm) | 595 |

Powertrain System

The WP12 electronically controlled engine conforms to the China-III non-road machinery emission regulation, featuring strong power, low fuel consumption, high intelligence and efficiency, high parts universality, and low maintenance cost. The normally-closed brake design is applied so that the machine is braked automatically after the stop of engine to ensure high safety. The four-point semi-suspension shock-absorbing installation reduces the machine vibration and improves the driving comfort. The shock absorbers in crossing shaft rubber block structure are applied to effectively mitigate the vibration from the engine and protect the engine and drive system.

Driving/Riding Environment

The ergonomic cab features large space, excellent vision, and good airtightness. The single accelerator pedal features comfortable operations. The seat and armrests with large adjustment range can provide comfortable operating posture. The cab adopts optimized shock-absorbing structure and sound-absorbing sponge to ensure low vibration and noise.

Operating Performance

The chassis system features long ground length, high ground clearance, stable driving, and excellent trafficability. Depending on specific working condition, the semi-U blade, straight tilting blade, angle blade, three-shank ripper, traction frame, and winch can be installed to achieve power operating capability. The standard LED working lamps improve the illumination capability and achieve higher safety and reliability during nighttime operations.

The traveling system is controlled by single hydroelectric control joystick to ensure comfortable and labor-saving operations. The hydraulic pilot control is applied for the working device to achieve low operating force and good reliability.

Easy Maintenances

The structural parts inherit the excellent quality of Shantui’s mature products; The electric harnesses adopt seamless corrugated pipes and deconcentrators for branching, featuring high protection grade. The core electric and hydraulic parts are globally procured to ensure stable quality and high reliability. The machine adopts the modular design to achieve easy disassembling and assembling, simple repairs, and easy maintenances.