Product Display

Video

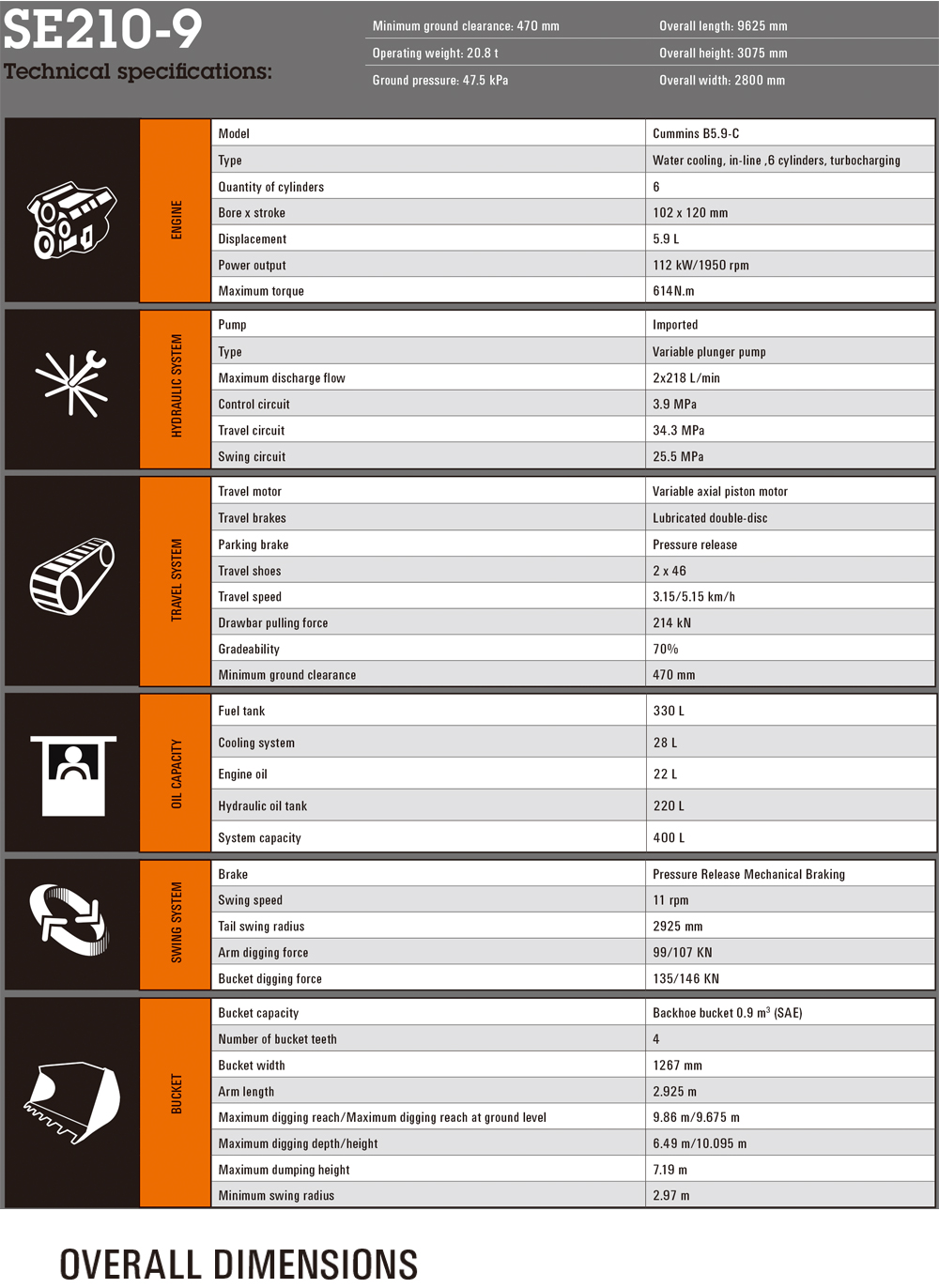

| Comparative item | SE210-9 |

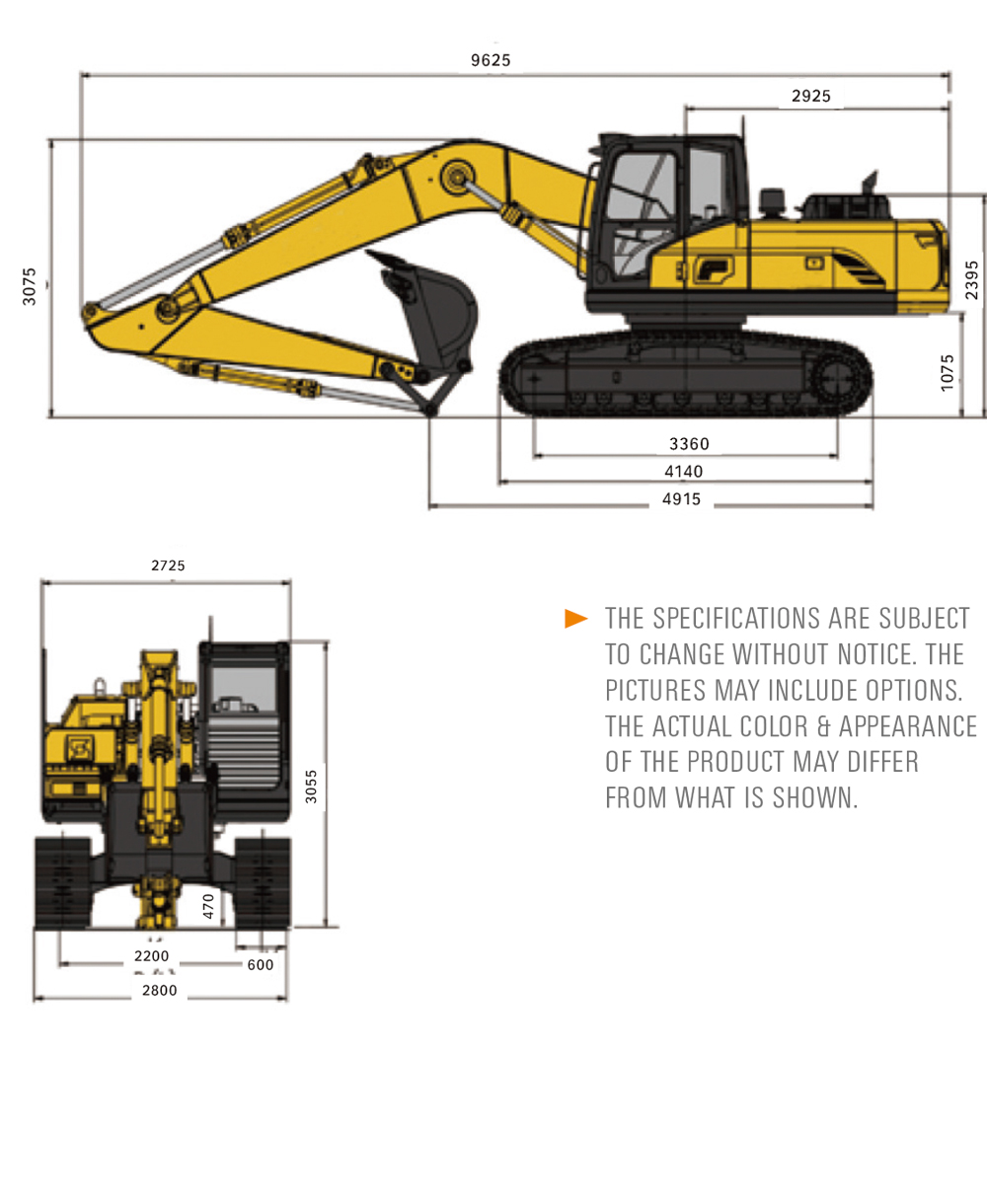

| Overall dimensions | |

| Overall length (mm) | 9625 |

| Ground length (During transport) (mm) | 4915 |

| Overall height (To the top of boom) (mm) | 3075 |

| Overall width (mm) | 2800 |

| Overall height (To top of cab) (mm) | 3055 |

| Ground clearance of counterweight (mm) | 1075 |

| Minimum ground clearance (mm) | 470 |

| Tail turning radius (mm) | 2925 |

| Track length (mm) | 4140 |

| Track gauge (mm) | 3360 |

| Track width (mm) | 2800 |

| Standard track shoe width (mm) | 600 |

| Turntable width (mm) | 2725 |

| Distance from slewing center to tail (mm) | 2920 |

| Working range | |

| Maximum digging height (mm) | 10095 |

| Maximum dumping height (mm) | 7190 |

| Maximum digging depth (mm) | 6490 |

| Maximum vertical digging depth (mm) | 5915 |

| Maximum digging distance (mm) | 9860 |

| Maximum digging distance at ground level (mm) | 9675 |

| Working device minimum turning radius (mm) | 2970 |

| Engine | |

| Model | Dongfeng Cummins B5.9-C |

| Type | 6-cylinder inline and water-cooled and turbocharged |

| Displacement (L) | 5.9L |

| Rated power (kW/rpm) | 112kW/1950rpm |

| Hydraulic system | |

| Type of hydraulic pump | Variable displacement plunger pump |

| Rated working flow (L/min) | 2x218L/min |

| Bucket | |

| Bucket capacity (m鲁) | 0.90m3 (SAE) |

| Swing system | |

| Maximum swing speed (r/min) | 11r/min |

| Brake type | Mechanically applied and pressure released |

| Digging force | |

| Bucket arm digging force (KN) | 99kN/107KN |

| Bucket digging force (KN) | 135kN/146KN |

| Operating weight and ground pressure | |

| Operating weight (kg) | 20800kg |

| Ground pressure (kPa) | 47.5KPa |

| Traveling system | |

| Traveling motor | Axial variable displacement plunger motor |

| Traveling speed (km/h) | 3.15/5.15km/h |

| Traction force (KN) | 214kN |

| Gradeability | 70% (35掳) |

| Tank capacity | |

| Fuel tank capacity (L) | 330L |

| Cooling system (L) | 28L |

| Engine oil capacity (L) | 22L |

| Hydraulic oil tank/system capacity (L) | 270/400L |

Certificate

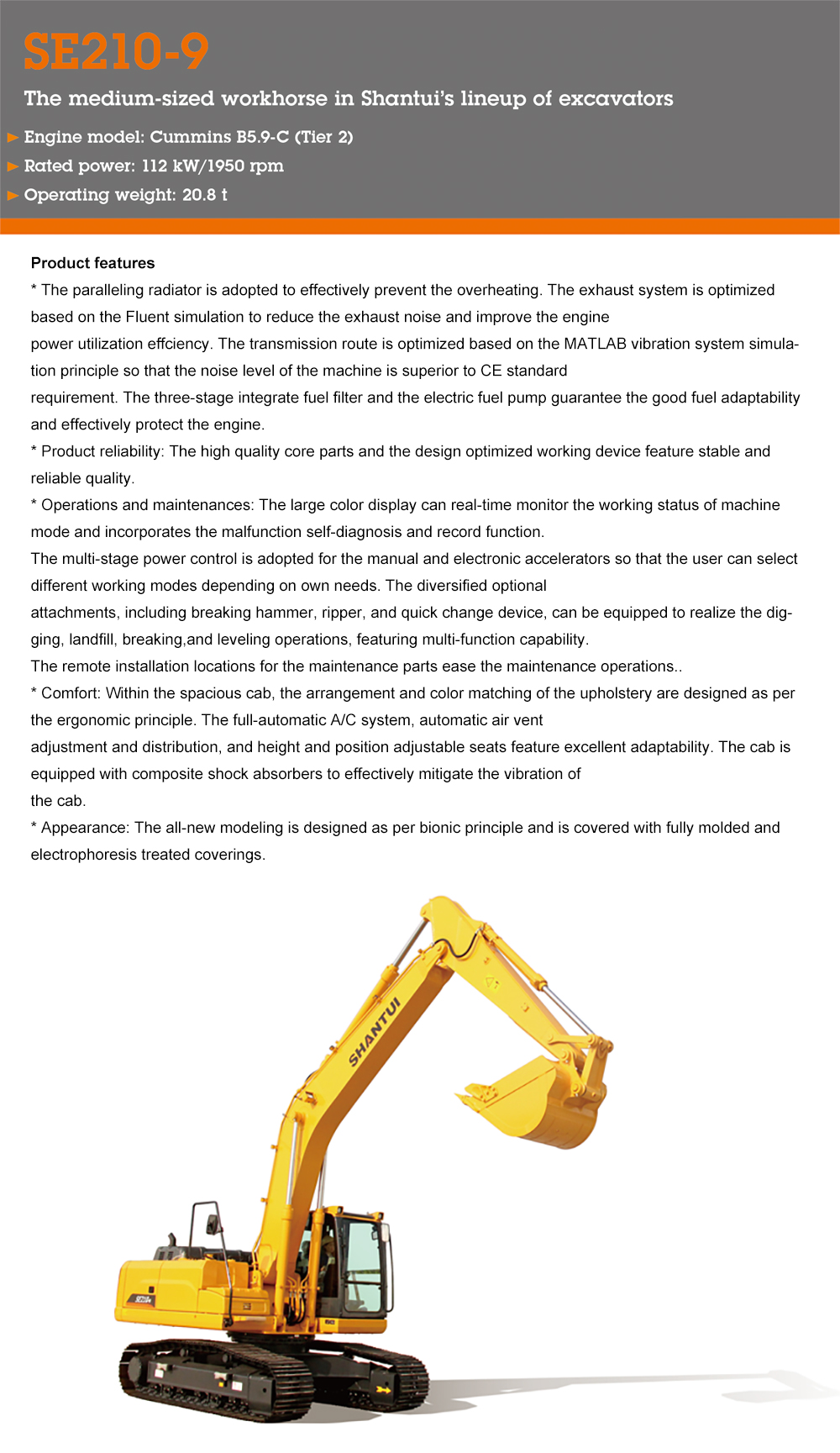

CHARACTERISTIC

High-end system configuration Cummins B5.9 six-cylinder engine conforms to China-II emission regulation and features strong power and high durability. It’s equipped with three-stage fuel filtration system to safeguard the working. The optimized negative-flow control hydraulic system features reliable performances and easy maintenances. The large displacement main pump perfectly matches with the engine to achieve higher machine speed Firm and durable structural parts 1. It’s equipped with standard reinforced bucket. 2. The cast front support is attached with reinforcement panels at key portions to achieve higher reliability. 2. The cast casing is used for the boom front yoke and rear seat to carry multi-direction variable torque loads. 4. The undercarriage in X-shaped box structure ensures high carrying capacity and the thickened panels are applied at key portions to improve reliability and durability Comfortable and convenient operating environment It’s installed with standard radio with USB port, cigarette lighter, fire extinguisher, and escape hammer and is provided with multiple storage spaces. The functional buttons are centrally arranged to ease the operations and achieve high elegance. The cab features large space and broad vision and the control devices are reasonably arranged to realize convenient and comfortable operations. The seat features high comfort and fatigue-resistance. The Denso high-power automatic A/C system features strong airflow output and multi-directional air vents without dead angle Intelligent electronic control and optimal power control The intelligent electronic control system perfectly matches with power system and hydraulic system to improve economy. The accelerator percentage control realizes the accurate match between engine output power and load demand Convenient maintenances 1. Supported by two cylinders, the backward-opening engine hood features handy opening, large opening angle, and easy maintenances. 2. The electric parts are centrally arranged to ease the checking and maintenances. 3. The filling of coolant and the replacement of air filter element are easily accessible and the assembled radiator mesh enclosure eases the cleaning. 4. The three-stage fuel filter element is installed to achieve one-stop replacement and easy maintenances. The fuel filter element, engine oil filter element, and pilot filter element are centrally arranged so that all maintenances and replacements can be completed from on same position 5. The lubricating oil filler ports are centrally arranged to easy the routine maintenances Optional equipment of machine Refueling pump Cab warning lamp Cab ceiling lamp Cab overhead protective net Cab front upper protective net Cab front lower protective net Rubber track Optional attachments Crusher Ripper Timber grab Hydraulic tamper Stone grab Breaking hammer pipelineSpecification